Model development for efficient simulation of CO2 storage, 2018

Tore Ingvald Bjørnarå

Main content

Advisors: Jan Martin Nordbotten and Joonsang Park

Short description of project:

Carbon capture and storage (CCS) is an important component of several initiatives to reduce global greenhouse gas emissions by injecting and storing CO2 in underground reservoirs. Simulation technology plays an important role in providing storage capacity estimates and analyzing long-term safety and risk factors of leakage to the surface. Two of several important questions that need to be answered before a storage project may be approved is how fast and how much CO2 can be injected without compromising the integrity of the sealing caprock, which stops it from migrating to the surface.

To evaluate the integrity we rely on mathematical models, but due to the large extent of the area that needs to be considered and the many processes that are involved the calculations can quickly become large and complicated and very time consuming to solve. For screening purposes of potential storage sites, or investigation of potential storage sites when little data is available, many model realizations are needed, thus fast and robust yet accurate numerical techniques are not only tractable but also essential.

To understand what happens to the CO2, formation water and rock during injection and storage, we have thoroughly reviewed the main processes that are relevant to the integrity of the reservoir and sealing formations. These main processes are fluid flow, stress change and temperature change and they are all coupled where for instance a change in pore pressure and temperature due to CO2 injection causes deformations and stress alterations that can affect the integrity of the injection reservoir and caprock.

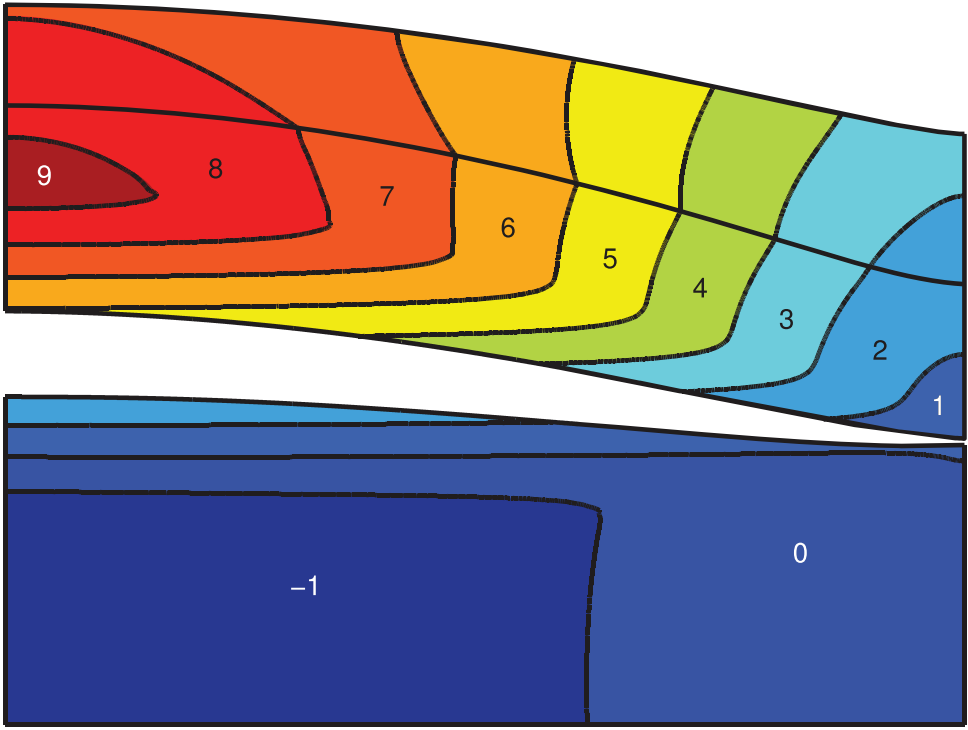

Considering the low solubility of CO2 in formation water under typical storage con- ditions (depth, temperature, pressure and salinity) we have illustrated that it is a good approximation to treat the injected CO2 and formation water as two separate fluids. Miscibility is therefore not an important process to consider in relation to long-term mechanical integrity and this simplifies the mathematical description of fluid flow.

Whether the thermo-hydro-mechanical coupling, where the temperature change is also considered, is important to evaluate is less obvious. Through examples we show that the in situ temperature is important to consider when estimating material proper- ties, but the effect of the cold (CO2) injection, relative to the storage formation, is very local and mainly affects the near-field of the injector. The cooling effect reduces the spreading of the CO2, but has little effect on the pore pressure. In general, cold injec- tion (relative to formation temperature) lowers the fracture pressure of the rock and the limit for maximum sustainable injection rate, and therefore, ignoring non-isothermal effects can underestimate the risk of failure, and vice versa for hot injection. A risk analysis of reactivation of faults in the sealing formation in the CO2 storage project at In Salah, Algeria, revealed that the thermal effect can make the difference between safe and risky storage.

To achieve a procedure for faster numerical evaluation, the layering structure and high aspect ratio of typical storage reservoirs can be used to simplify the mathematical description of the internal physical processes using a method of dimensional reduction. This has previously been found particularly attractive in simulating the migration of CO2 in the context of CCS. Since hydro-mechanical coupling is particularly essential to consider when evaluating the integrity of the caprock, we have extended this concept to also include the geomechanical processes. The underlying assumptions of negligible vertical flow compared to horizontal flow (Vertical Equilibrium, VE, assumption) and linearly varying displacement across the thickness of the reservoir (Linear Vertical Deflection, LVD, assumption) has proved promising in providing significant savings in computational time and effort with up to more than ten times faster calculations compared to a full-dimensional model. It has also been demonstrated that such models can retain a high accuracy when applied to realistic field data, such as the conditions at the CO2 storage plant at In Salah, Algeria. Also, the range of applicability of the dimensionally reduced model is to a leading order the thickness of the reduced domain and accurate solutions in the order of 0.1 % and less difference in solution compared to a full-dimensional formulation for aquifers up to 100 meters thick has been achieved.

Link to thesis at BORA-UiB: http://bora.uib.no/handle/1956/17695